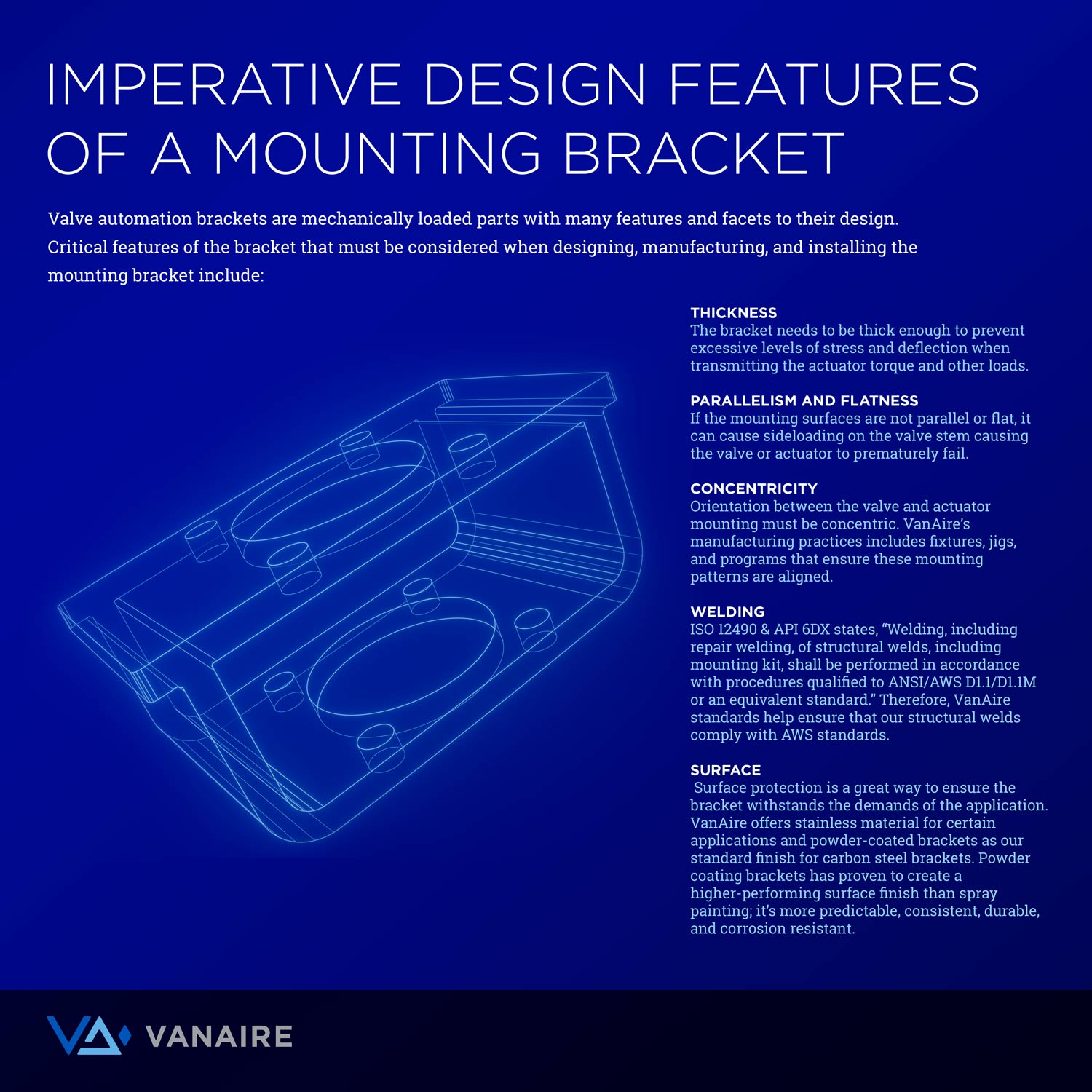

Mounting Brackets

For years, many have overlooked the importance of this bracket and often called it “just a piece of bent metal” or “just a piece of square tubing.” VanAire understands that without a solid frame of a robust mounting kit, the entire valve assembly is at risk for not functioning properly.

Just like the frame of your truck – the main supporting structure of a motor vehicle to which all other components are attached – the mounting bracket is the structural foundation of the mounting kit that connects between the actuator and the valve. The truck’s frame and the mounting bracket support the mechanical components; deal with static and dynamic loads without undue deflection or distortion; and must handle the torque from the power source .

The design of the mounting bracket should not only consider the stresses and strains developed from the applied loads (actuator torque, actuator weight, etc.) but also consider deflection. Excessive deflections (angular twist and/or bending) could prevent the valve and actuator from functioning properly. “Deflections of the mounting kit shall not prevent the valve closure member from reaching the fully closed or fully open position or restrict actuator functionality” (API 6DX, 2020). Except for special circumstances (e.g., extended mounting heights with horizontal stem orientations), mounting kits should be able to be installed in any orientation without additional support.

Engineered Valve Automation Hardware

The Engineered Difference.

Check out our recent spotlight in Valve World Americas titled “VanAire: The Engineered Difference” outlining our unique approach to Valve Automation Hardware.

Check out our recent spotlight in Valve World Americas titled “VanAire: The Engineered Difference” outlining our unique approach to Valve Automation Hardware.