Thank you!

We’ll be in touch.

Since 1995

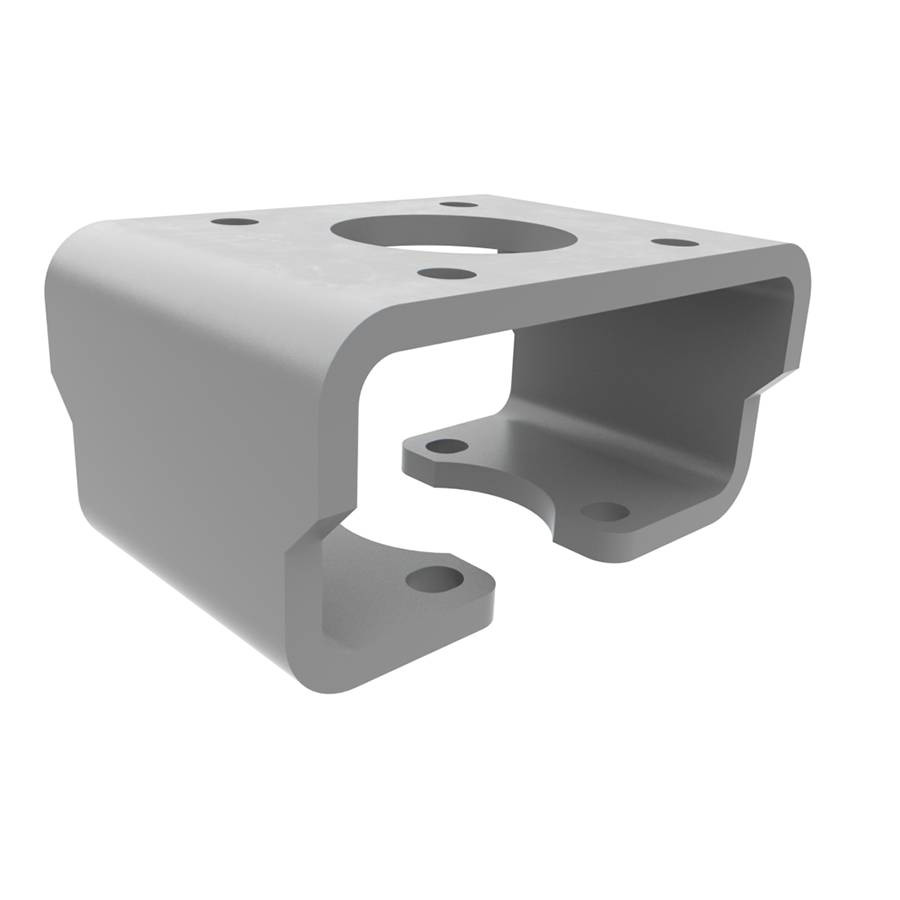

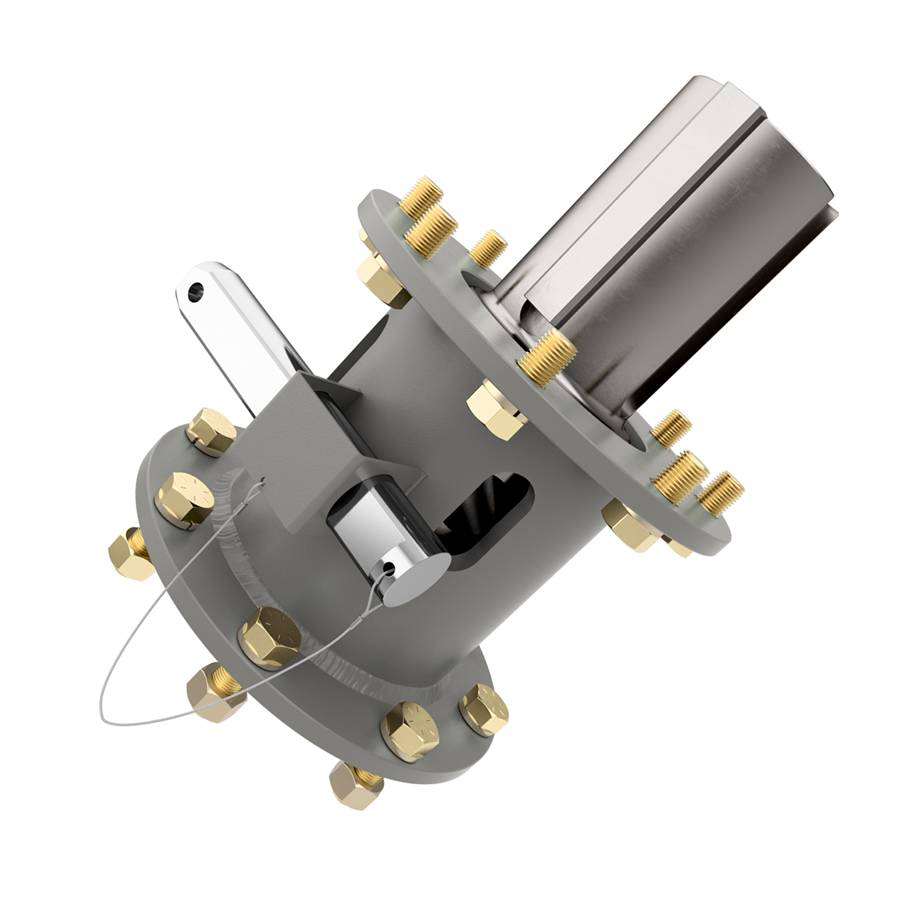

Engineered Valve Automation Hardware has been a core VanAire product for over 25 years. We strive to set the industry benchmark and, due to our Engineering, Manufacturing and Quality capabilities, have been recognized across North America and beyond as the primary go-to source of many leading valve and actuator companies and their distributors.

Through our involvement with industry trade groups we collaborate with leaders around the world to increase the overall efficiency of the final product and reduce downtime.

“An automated valve assembly is an engineered product and should be treated as such. So all the components that are selected – the valve, the actuator, the bracket, the solenoid, the switchbox, etc. – should have been built to the same high standard and should be compatible with each other. A chain is only as strong as the weakest link.”

Kees Meliefste, Dow Chemical – Sr. Instr. Specialist

ISO 9001:2015 Certified

VanAire has been ISO 9001 certified since 2012. ISO 9001:2015 is a globally recognized Quality Management System that VanAire has integrated into our business philosophy by focusing on core principles including: a strong customer focus, building a highly trained and respected team, involvement of high-level company management, a process-based approach for engineering and manufacturing, and ongoing process improvements. All of these principles are designed to provide solutions and value for our customers.

Engineered Valve Automation Hardware

The Engineered Difference.

Check out our recent spotlight in Valve World Americas titled “VanAire: The Engineered Difference” outlining our unique approach to Valve Automation Hardware.

Check out our recent spotlight in Valve World Americas titled “VanAire: The Engineered Difference” outlining our unique approach to Valve Automation Hardware.

A Skilled Team

Within VanAire’s 45,000-square-foot facility in Gladstone, Michigan, visitors will find more than 75 skilled professionals including our customer service team, professional and mechanical engineers, certified solidworks professionals (CSWP), American Welding Society (AWS) certified welding inspectors and qualified welders, and American Society of Mechanical Engineers (ASME) section IX welders utilizing the following state-of-the-art resources: 15 3D CAD stations with FEA capabilities, more than 30 CNC machines including robotic welders, laser-cutting systems, machining centers, turning centers, press brakes, blind hole keyseaters, and robotic machine tenders.